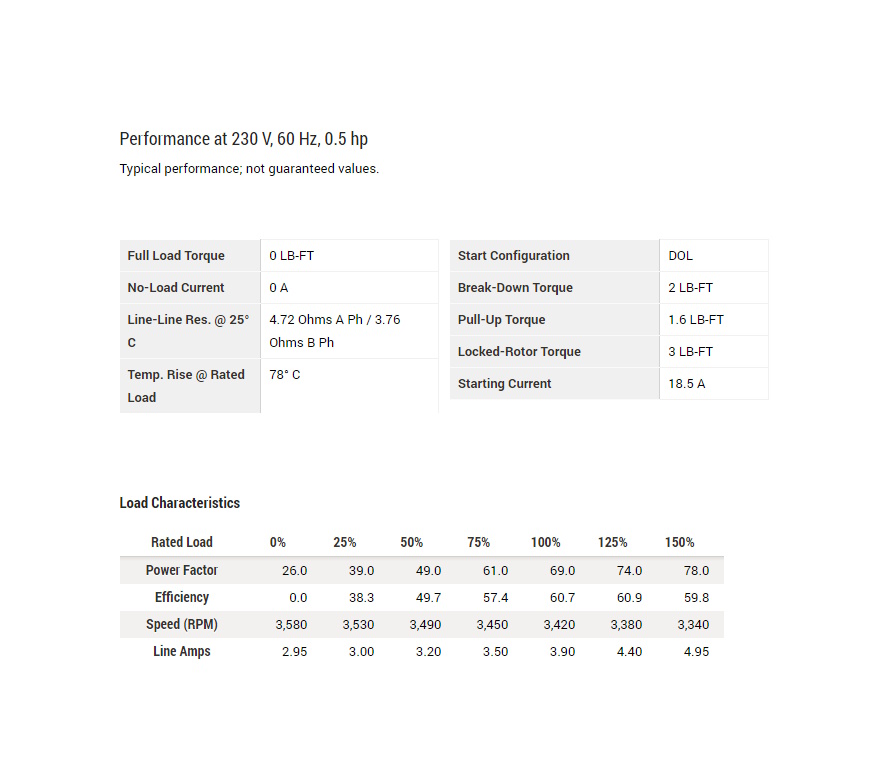

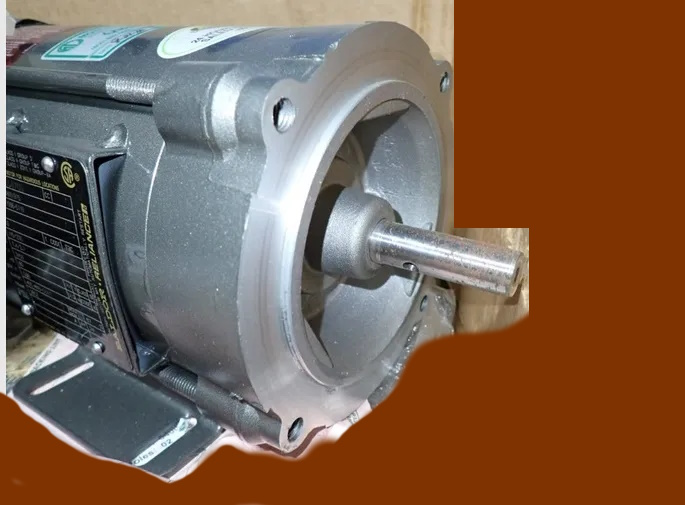

Description

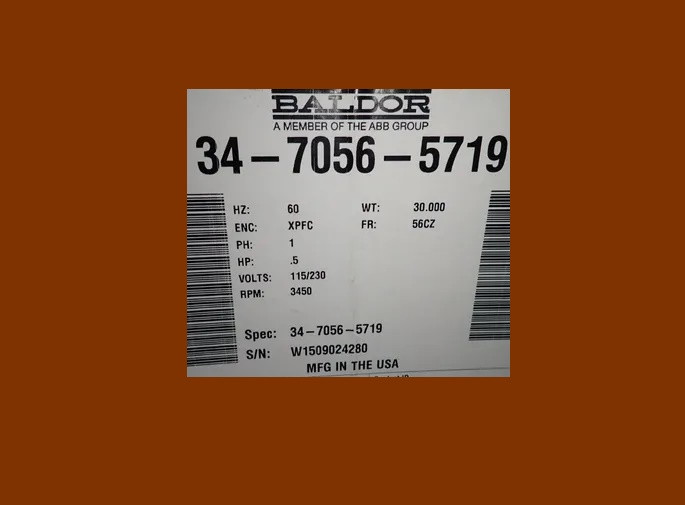

Baldor Motor Spec 34-7056-5719

Several Available

CM2739

No. C12314701

0.5 HP

T Code T3C

UL Listed

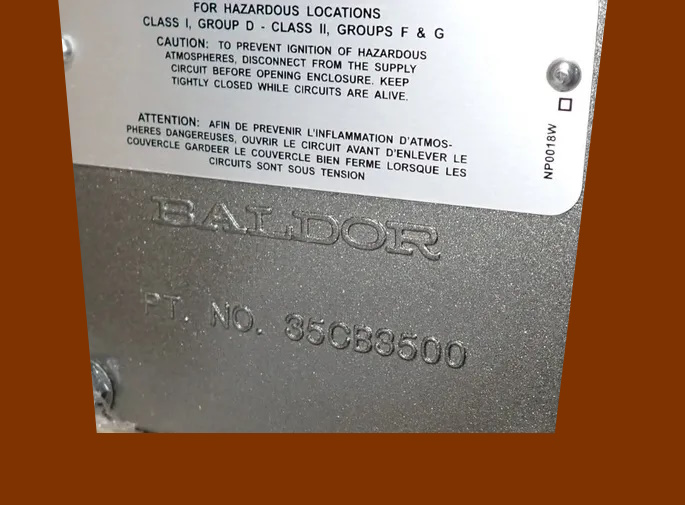

Electric Motor for Hazardous Locations

Enclosure XPFC

Frame 56CZ

Frame Material Steel

Frequency 60.00 Hz

Motor Letter Type Cap Start, Induction Run

Output @ Frequency .500 HP @ 60 HZ

Phase 1

Synchronous Speed @ Frequency 3600 RPM @ 60 HZ

Voltage @ Frequency 230.0 V @ 60 HZ

115.0 V @ 60 HZ

XP Class and Group CLI GP D; CLII GP F,G

XP Division Division I

Agency Approvals CSA UL

Ambient Temperature 40 °C

Auxillary Box Lead Termination None

Base Indicator Rigid

Bearing Grease Type Polyrex EM (-20F +300F)

Blower None

Current @ Voltage 7.400 A @ 115.0 V

3.700 A @ 230.0 V

Design Code N

Drip Cover No Drip Cover

Duty Rating CONT

Efficiency @ 100% Load57.0 %

Electrically Isolated Bearing Not Electrically Isolated

Feedback Device NO FEEDBACK

High Voltage Full Load Amps3.7 a

Front Face Code Standard

Front Shaft Indicator None

Heater Indicator No Heater

Insulation Class B

Inverter Code Not Inverter

IP Rating NONE

KVA Code K

Lifting Lugs No Lifting Lugs

Locked Bearing Indicator No Locked Bearing

Motor Lead Exit Ko Box

Motor Lead Termination Flying Leads

Motor Lead Quantity/Wire Size 6 @ 18 AWG

Motor Type X3416L

Mounting Arrangement F1

Number of Poles 2

Overall Length 13.22 IN

Power Factor 71

Product Family Hazardous Location Motor

Pulley End Bearing Type Ball

Pulley Face Code C-Face

Pulley Shaft Indicator Special Combination

Rodent Screen None

Service Factor 1.00

Shaft Diameter 0.625 IN

Shaft Extension Location Pulley End

Shaft Ground Indicator No Shaft Grounding

Shaft Rotation Reversible

Shaft Slinger Indicator No Slinger

Speed 3450 rpm

Speed Code Single Speed

Motor Standards NEMA

Starting Method Direct on line

Thermal Device – Bearing None

Thermal Device – Winding None

Vibration Sensor Indicator No Vibration Sensor

Winding Thermal 1 Automatic Thermal Overload

Winding Thermal 1 Location EP

Winding Thermal 2 None

XP Temp Code T3C

30lbs, 17 x 12x 11